Project Summary

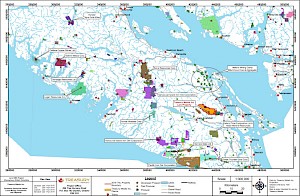

Treasury Metals Inc. holds a 100% interest in certain mineral claims that constitute the Lara Project located approximately 25 km west of the Village of Chemainus, Vancouver Island, British Columbia. The project hosts the Lara copper-lead-zinc-gold-silver deposit. Treasury Metals (under the previous owner Laramide Resources, prior to a corporate reorganization) had proposed mining the Coronation and Coronation Extension zones of the deposit and transporting the ore for final processing at an existing mine and mill owned by Breakwater Resources Ltd. The Myra Falls Operation, now owned by Nystar, is situated in Strathcona Provincial Park, accessible by truck and/or barge from the Lara Project. The project has nearby highway access, ports and power located at site.

The project is a highly prospective region for targeting stratabound, high-grade volcanogenic massive sulphide deposits, with emphasis on zinc in particular. Presently, Treasury Metals’ property position as of June 30, 2014, totals 6476.93 ha of registered mineral claims, with the possibility of further expanding the current property. Diamond drilling on the property totals upwards of 101,730 metres in 490 drill holes. The main resource, also known as the Coronation Trend was modeled using Datamine Studio as six discrete zones and consists of continuous pods of zinc and gold rich mineralization. The current resource estimate is based on the Coronation Trend, which includes the Coronation Zone, the Coronation Extension and the hanging wall deposit. The indicated resource estimate for a 1% zinc block cut off, contains approximately 1,146,700 tonnes, with an average grade of 3.01% zinc, 32.97 g/t silver, 1.05% copper, 0.58% lead, and 1.97 g/t gold. At the same cut off percentage, the inferred resource estimate is thought to contain another 669,600 tonnes, with an average grade of 2.26% zinc, 32.99 g/t silver, 0.90% copper, 0.44% lead, 1.90 g/t gold. The available digital elevation models were compiled using ArcMap. An independent mineral resource estimate in accordance with the guidelines set out in NI 43-101 has been completed on the project.

Based on metallurgical test work by previous operators at the project and past discussions with Mrya Falls Operational staff, it is believed that ore from the project will not require any significant adjustments to its current milling practices. In addition, it could potentially be blended with material from the Myra mine. Additional work is required to verify these comments.

Accessibility

The site is accessed by taking the Trans-Canada Highway to Chemanius and exiting at Copper Canyon road, travelling west for approximately seven km and then one km of operational logging roads. The highway between the town of Duncan (15 km northwest of Lara) and Campbell River could support the increase in heavy truck traffic that would be associated with the construction and operation of the project. The network of logging roads that cross-cut the region can easily be accessed by automobiles and are in good working order. The logging roads in the area also extend to most locations on the project and can be accessed by the Chemainus River Logging Trunk Road. There is a good outcrop exposure at the “262” mineralized zone that is easily accessed by vehicle. There is a sheltered core storage shed on site. The site does have a major BC Hydro power line running along the southwest perimeter of the project.

There is also access for transporting ore to the Myra Falls processing plant. All ore bearing rock can be transported by truck and picked up from the front gate. An outstanding issue with transporting ore using transport trucks is that the class A Strathcona Provincial Park would need to be crossed to reach the processing plant at Myra Falls. Permits and public support may be required if this is the method that will be used. Assuming, Myra Falls was willing to pick up the ore right from the gate, this is likely the most cost effective way of transporting material but the various options need to be analyzed further.

Another option for transporting ore bearing rock would be through the use of barges. The nearest facility to the project site is a deep-sea port facility at the port in Crofton. It terms of proximity the port is 15 km to the project and is currently used primarily by the forestry sector. Additional work needs to be done to obtain space at the port and to determine if an appropriate barge loading facility is available. Both methods bring added logistical, financial and social advantages and disadvantages. In addition, both methods have a variety of options to consider such as an ore-sorting system located at the Lara mine site that could significantly reduce transportation costs, grade control, and reduction of operating costs.

Future Programs

One objective that should be considered for future exploration on the project involves identifying additional mineralized zones along strike, through the use of geological and geophysical interpretations. This should be followed up by additional field work and possibly a geochemical survey to pinpoint potential areas of mineralization. Another objective would be to characterize the existing mineralized zones by commencing further drilling within the mineralized zones to enhance the current resource. There remains excellent potential to increase the current resource estimate and the discovery of additional massive sulphide mineralization by drilling at depth along strike of the already known mineralized zones. The areas that warrant further drilling are along strike to the northwest and to the southeast, associated with the McLaughlin Ridge Formation and the Sicker Group. To better identify any new potential mineralized zones further, interpretations of the 3D targeting work needs to be reviewed.

In addition, the technical, financial, social and political aspects of the project need to be advanced to a feasibility stage. In addition, transporting ore for final processing at Myra Falls Operation is a key consideration which needs to be analysed further. Current provincial and federal environmental regulations will require the project be subject to a full environmental impact assessment.